BLDC

motor

The BLDC motor is widely used in

applications including appliances, automotive, aerospace, consumer, medical,

automated industrial equipment and instrumentation.

The BLDC motor is electrically

commutated by power switches instead of brushes. Compared with a brushed DC motor or an

induction motor, the BLDC motor has many advantages:

- Higher efficiency and reliability

- Lower acoustic noise

- Smaller and lighter

- Greater dynamic response

- Better speed versus torque characteristics

- Higher speed range

- Longer life

a.

Motor Principles

Motors convert electrical energy

into mechanical energy using electromagnetic principles. The energy conversion

method is fundamentally the same in all electric motors.

b.

Stator

A single-phase motor has one stator

winding wound either clockwise or counter-clockwise along each arm of the

stator to produce four magnetic poles as shown in figure.

|

| Figure 1. Stator |

Each phase turns on sequentially to make the rotor revolve. There are two types

of stator windings: trapezoidal and sinusoidal, which refers to the shape of

the back electromotive force (BEMF) signal. The shape of the BEMF is determined

by different coil interconnections and the distance of the air gap. In addition

to the BEMF, the phase current also follows a trapezoidal and sinusoidal shape.

A sinusoidal motor produces smoother electromagnetic torque than a trapezoidal

motor, though at a higher cost due to their use of extra copper windings. A

BLDC motor uses a simplified structure with trapezoidal stator windings.

c.

Rotor

A rotor consists of a shaft and a

hub with permanent magnets arranged to form between two to eight pole pairs

that alternate between north and south poles. Figure shows cross sections of

three kinds of magnets arrangements in a rotor.

| |

| Figure 2. Rotor |

There are multiple magnet

materials, such as ferrous mixtures and rare-earth alloys. Ferrite magnets are

traditional and relatively inexpensive, though rare-earth alloy magnets are

becoming increasingly popular because of their high magnetic density. The

higher density helps to shrink rotors while maintaining high relative torque

when compared to similar ferrite magnets.

d.

Operational Motor Theory

Motor operation is based on the

attraction or repulsion between magnetic poles.

|

| Figure 3. 3 Phase motor |

Using the three-phase motor shown

in figure, the process starts when current flows through one of the three stator

windings and generates a magnetic pole that attracts the closest permanent

magnet of the opposite pole. The rotor will move if the current shifts to an

adjacent winding. Sequentially charging each winding will cause the rotor to

follow in a rotating field. The torque in this example depends on the current

amplitude and the number of turns on the stator windings, the strength and the

size of the permanent magnets, the air gap between the rotor and the windings,

and the length of the rotating arm.

Types of Motor

a.

Brushed DC Motor

A brushed DC motor consists of a

commutator and brushes that convert a DC current in an armature coil to an AC

current, as shown in figure.

As current flows through the

commutator through the armature windings, the electromagnetic field repels the

nearby magnets with the same polarity, and causes the winging to turn to the

attracting magnets of opposite polarity. As the armature turns, the commutator

reverses the current in the armature coil to repel the nearby magnets, thus

causing the motor to continuously turn. The fact that this motor can be driven

by DC voltages and currents makes it very attractive for low cost applications.

However, the arcing produced by the armature coils on the brush-commutator

surface generates heat, wear, and EMI, and is a major drawback.

b.

Brushless DC (BLDC) Motor

A BLDC motor accomplishes

commutation electronically using rotor position feedback to determine when to

switch the current. The structure is shown in figure.

Feedback usually entails

an attached Hall sensor or a rotary encoder. The stator windings work in

conjunction with permanent magnets on the rotor to generate a nearly uniform

flux density in the air gap. This permits the stator coils to be driven by a

constant DC voltage (hence the name brushless DC), which simply switches from

one stator coil to the next to generate an AC voltage waveform with a

trapezoidal shape.

c. AC Induction Motor (ACIM)

A sinusoidal AC current runs through the stator

to create a rotating variable magnetic field that induces a current in the

rotor (typically made of non-ferrous materials). This induced current

circulates in the bars of the rotor to generate a magnetic field. These two

magnetic fields run at different frequencies (usually ω-s>ω-r

for the motor) and to generate torque. Figure shows the motor structure.

d. Permanent Magnet Synchronous Motor (PMSM)

The PMSM motor shares some similarities with the

BLDC motor, but is driven by a sinusoidal signal to achieve lower torque

ripple. The sinusoidal distribution of the multi-phase stator windings

generates a sinusoidal flux density in the air gap that is different from BLDC

motor’s trapezoidal flux density. However, newer designs can achieve this

sinusoidal flux density with concentrated stator windings and a modified rotor

structure. Rotor magnet position can significantly alter the electrical

properties of a PMSM; Mounting the rotor magnets on the surface as shown in figure results in lower torque ripple, while burying

the magnets inside the rotor structure as shown in figure increases saliency, which increases the

reluctance torque of the motor. The structure of PMSM is shown in figure.

e. Stepper Motor & Switched Reluctance (SR)

Motor

Both stepper motors and SR motors have similar

physical structures; The stator consists of concentrated winding coils while

the rotor is made of soft iron laminates without coils. It has a doubly salient

structure (teeth on both the rotor and stator) as shown in figure.

Stepper motors are designed to replace more expensive servo motors. When

the current switches from one set of stator coils to the next, the magnetic

attraction between rotor and stator teeth induces enough torque to rotate the

rotor to the next stable position, or "step." The rotation speed is

determined by the frequency of the current pulse, and the rotational distance

is determined by the number of pulses. Since each step results in a small

displacement, a stepper motor is typically limited to low-speed

position-control applications.

There is no reactive torque (magnet to magnet)

in an SR motor because the rotor cannot generate its own magnetic field.

Instead, both rotor and stator poles have protrusions so that the flux length

is a function of angular position, which gives rise to saliency torque. This is

the only torque-producing mechanism in an SR motor, which tends to result in

high torque ripple. However, due to their simple design, SR motor is very

economical to build, and is perhaps the most robust motor available.

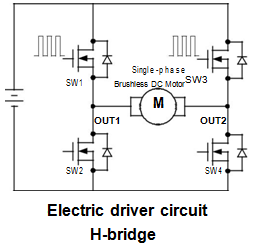

a. Switch Configuration and PWM

Brush-less DC motors use electric switches to

realize current commutation, and thus continuously rotate the motor. These

electric switches are usually connected in an H-bridge structure for a

single-phase BLDC motor. Usually the high-side switches are controlled using

pulse-width modulation (PWM), which converts a DC voltage into a modulated

voltage, which easily and efficiently limits the startup current, control speed

and torque. Generally, raising the switching frequency increases PWM losses,

though lowering the switching frequency limits the system’s bandwidth and can

raise the ripple current pulses to the points where they become destructive or

shut down the BLDC motor driver.

b. Electronics Commutation Principle of Single-Phase

BLDC Motor

BLDC commutation relies on feedback on the rotor

position to decide when to energize the corresponding switches to generate the

biggest torque. The easiest way to accurately detect position is to use a position

sensor. The most popular position sensor device is Hall sensor. Most BLDC

motors have Hall sensors embedded into the stator on the non-driving end of the

motor. figure shows the commutation sequence of a single-phase

BLDC motor driver circuit.

The permanent magnets form the rotor and are

located inside the stator. A Hall position sensor (“a”) is mounted to the

outside stator, which induces an output voltage proportional to the magnetic

intensity (assume the sensor goes HIGH when the rotor’s North Pole passes by,

and goes LOW when the rotor’s South Pole passes by). SW1 and SW4 turn on when

Hall sensor output is HIGH, as shown in figure.

At this stage, armature current flows through

the stator windings from OUT1 to OUT2 and induces the alternate stator

electromagnetic poles accordingly. The magnetic force generated by rotor

magnetic field and stator electromagnetic field causes the rotor to rotate.

After the rotor signal reaches 180°, the Hall output voltage reverses due to

its proximity to a South Pole. SW2 and SW3 then turn on with current reversing

from OUT2 to OUT1, as shown in figure. The opposite stator magnetic poles induce the rotor to continue

rotating in the same direction.

Figure shows an example of Hall sensor signals with respect to switch drive

signals and armature current. The armature current exhibits a saw tooth

waveform due to PWM control. The applied voltage, switching frequency, and the

PWM duty cycle are three key parameters to determine the speed and the torque

of the motor.

dedektör

ReplyDeletededektör

dedektör

dedektör

elektrische Pfeffermühlen oder auch electric Peppermills. Awesome article post.Much thanks again. Much obliged.

ReplyDeleteQuick snack fix, super easy. buy a vending machine

ReplyDelete